Featured Projects

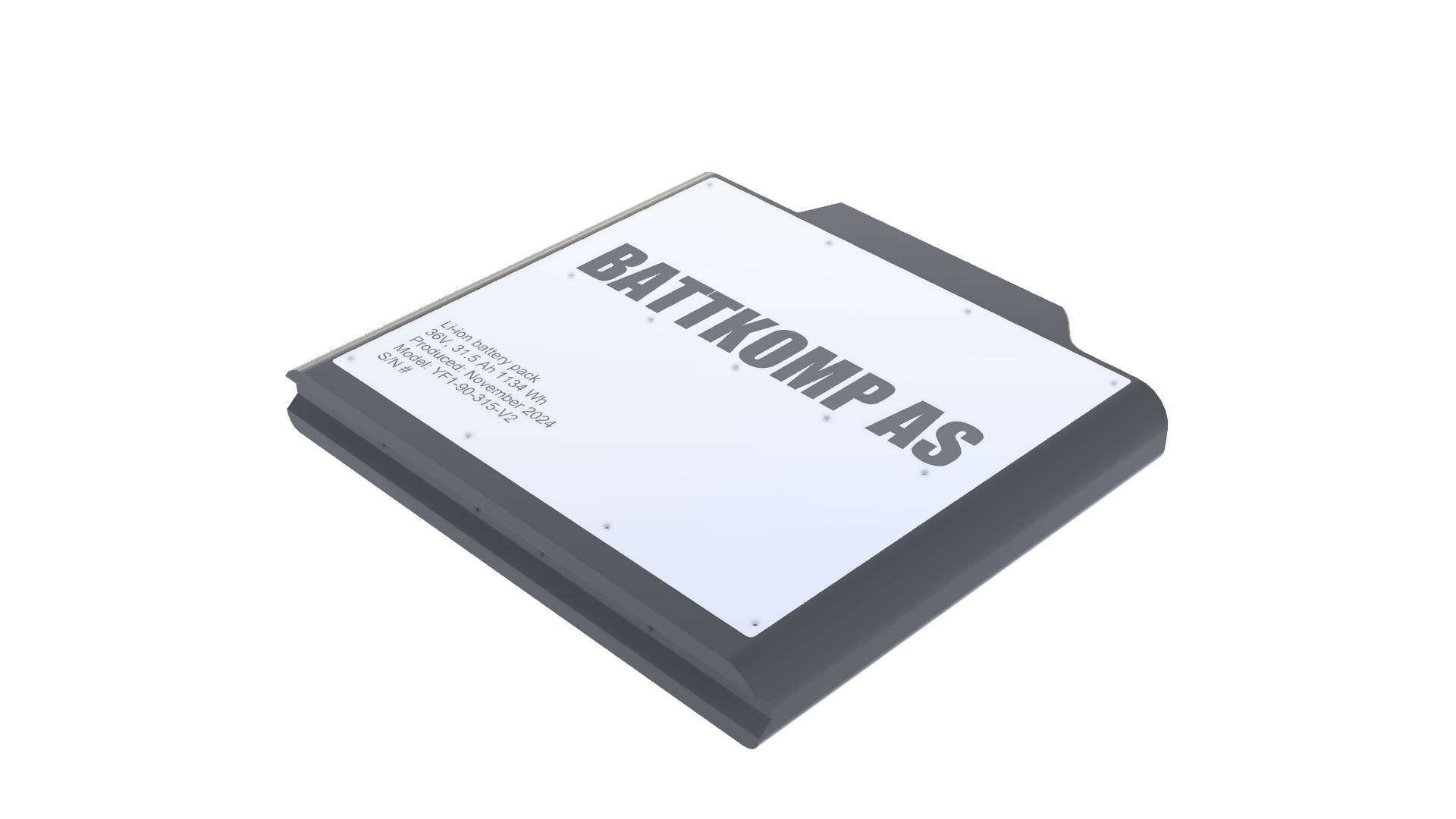

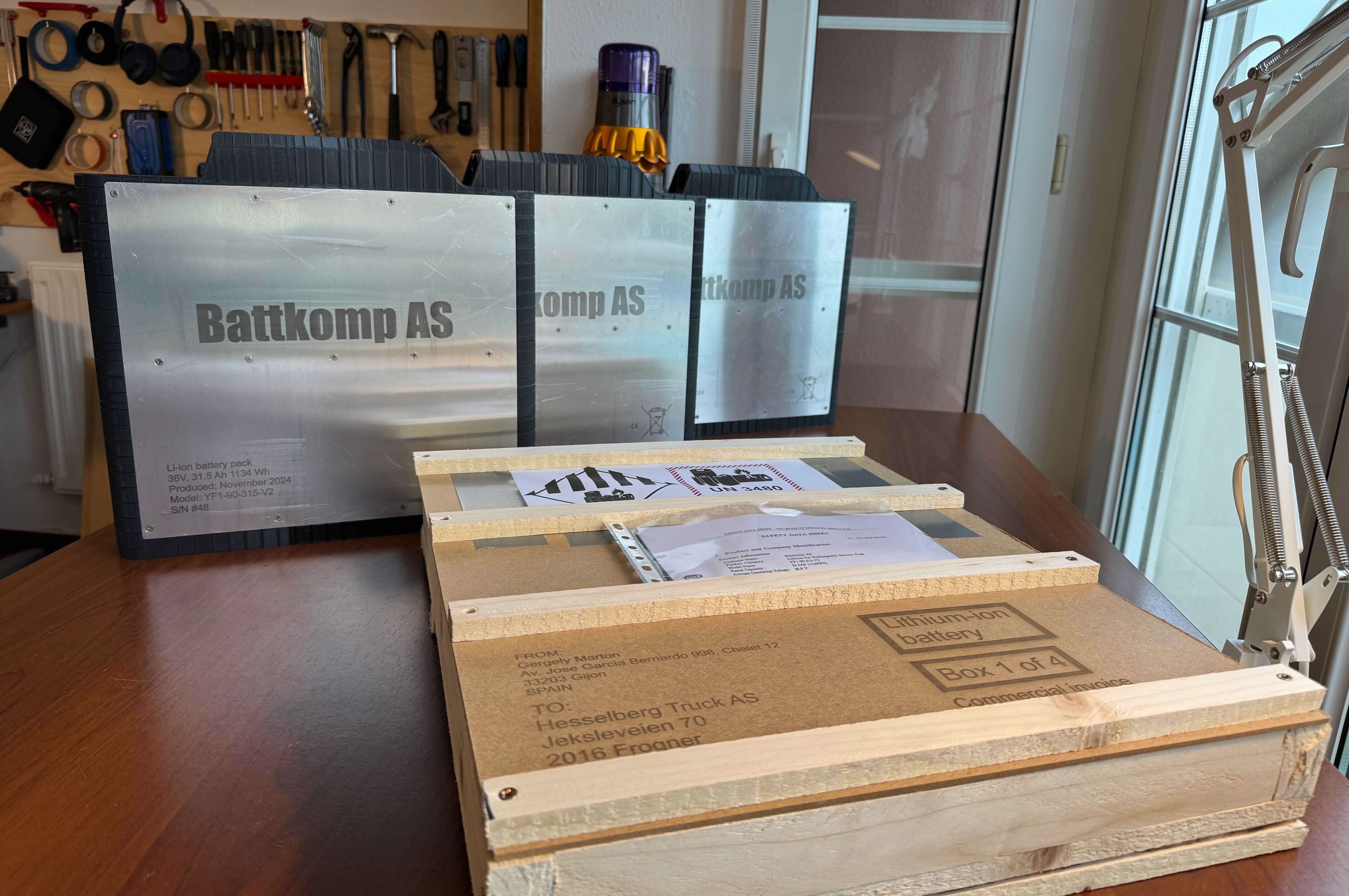

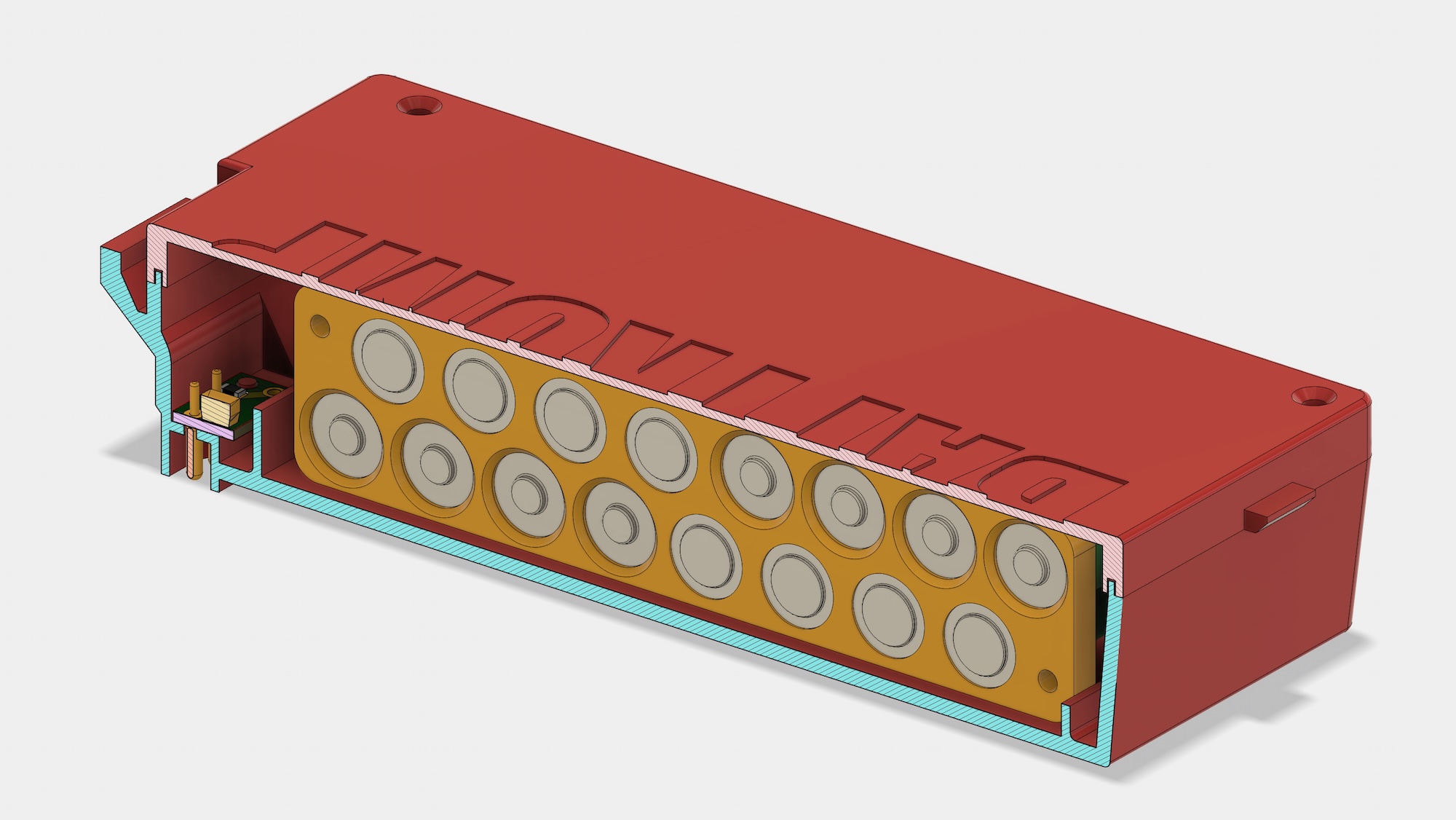

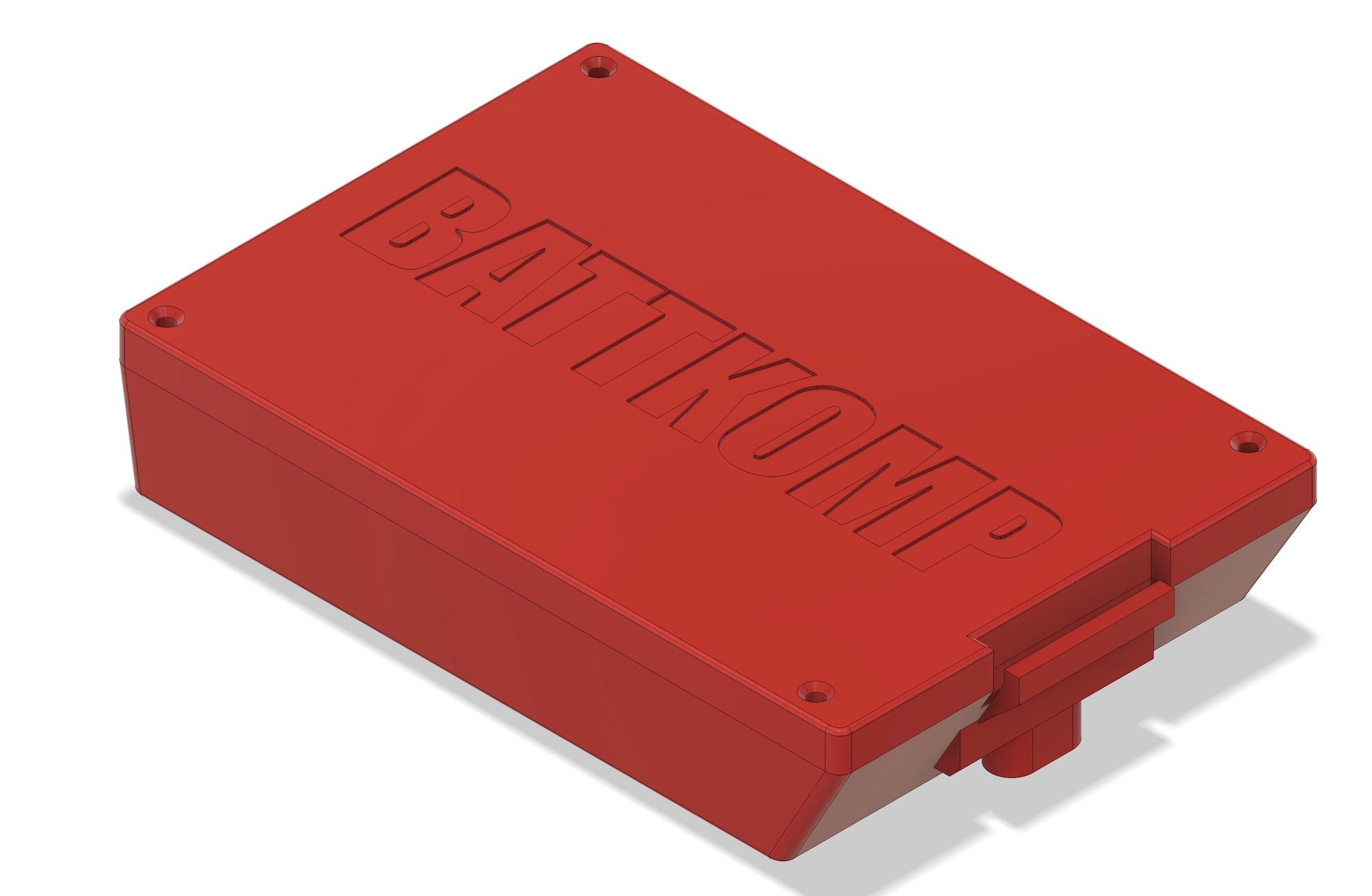

CiTi One Pallet Jack

1 kWh lithium-ion battery solution with custom housing and communication system. Successfully scaled to 50-unit production.

Compatible with STILL / Linde CiTi One pallet jacks, replacing the low-capacity, expensive, heavy, and short-lived NiMH batteries.

MOVEXX Replacement Battery

24V, 17Ah non-spill lead-acid battery solution featuring sheet metal forming and hybrid construction techniques.

Compatible with MOVEXX smart electric tugs of the TT1000 and TT1500 series.

Defibrillator Batteries

150+ units produced with 100% in-house design, featuring custom authentication systems and compact form factors.

Single use alkaline battery based on standard AA cells.

Wolfast UniOvi Racing

Racing motorcycle battery project in collaboration with the University of Oviedo MotoStudent Team, featuring custom BMS and thermal management.